Small Batches, Smaller Ecological Impact

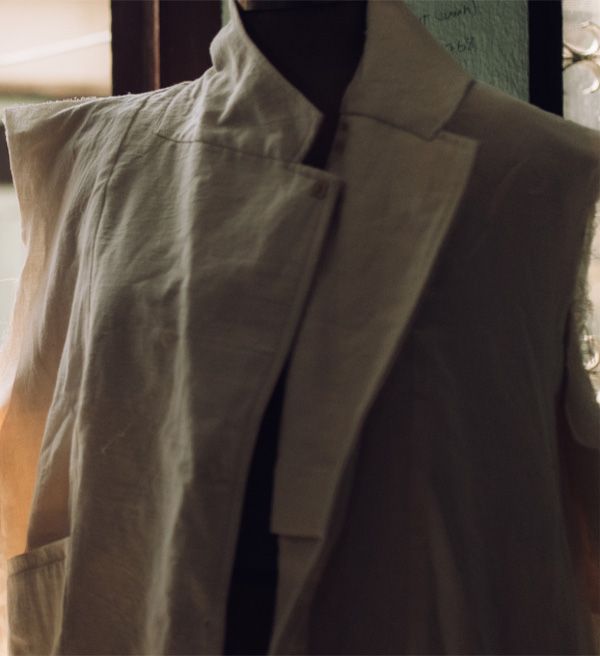

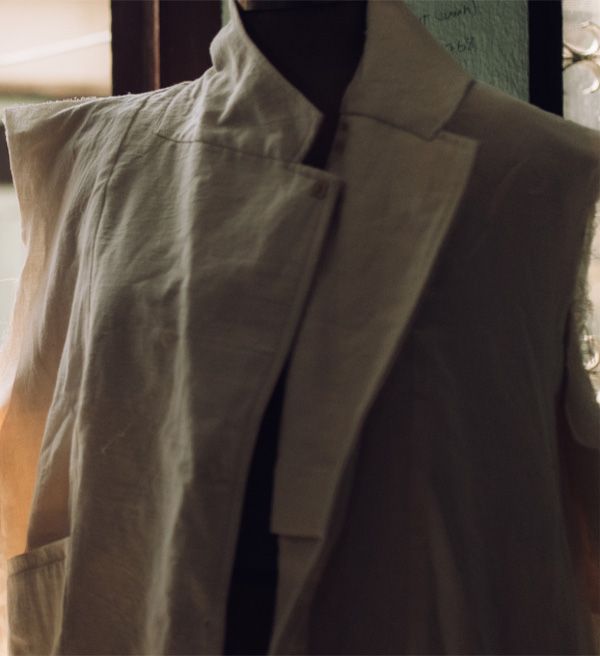

At Jijivisha, we take a different approach. All of our garments are cut and sewn in small batches. This helps us stay intentional, avoid excess inventory, and reduce waste before it begins.

Producing in small batches also allows us to work closely with small, independent tailoring units rather than outsourcing to large factories. This fosters not only better quality control but more meaningful relationships with our partners.

We visit our tailors regularly—not just to check in on production, but to stay connected with the people behind our clothes.

Over the past two years, we’ve witnessed the small workshop we collaborate with grow steadily—investing in new sewing machines and hiring more tailors and seamstresses to keep up with demand.

This kind of growth—slow, steady, human-centered, and eco-conscious—is what we believe fashion should look like. It’s not just about making garments; it’s about building a supply chain rooted in dignity, mutual respect (for humans and earth) and long-term sustainability.